Core Materials: Differences in Metal Coils | Ferrite vs. Metal

Metal-based coils may appear similar, but their performance can differ greatly depending on the molding method. Here’s a look at how different molding techniques impact the performance of metal coils in Sagami Elec’s lineup.

The three types in Sagami Elec’s lineup each use a different molding method, but it is difficult to distinguish them by appearance alone.

Metal core molding methods are mainly divided into three types. Cold pressing provides the most standard characteristics, while T-core structures tend to deliver the best performance.

| Molding Method | Performance | Sagami Line up |

|---|---|---|

| Cold Pressing | Standard characteristics | XRK-B |

| Hot Pressing | Enhanced DC superposition | XRK-D |

| T-core | Optimized performance with low DCR | XRJ |

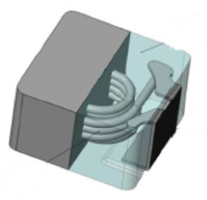

Depending on the molding method, the internal structure of the coil differs, resulting in the following configurations:

cold-formed and hot-formed products

In both cold and hot forming, metal powder is filled around an air-core coil and then compression-molded. Cold forming uses lower temperatures, while hot forming uses higher temperatures.

T-core

A T-core is combined with an air-core coil, and the area around the air-core coil is then pressed with metal powder to form the final shape.

As an example of how molding methods affect performance, the characteristics of XRK0730B, XRK0754D, and XRJ0754 are compared below.

*Note: Since XRK0730B differs in size, adjustments were made: the increase in the low-area portion was applied to the core diameter, and the increase in product height was reflected in the DCR.

| DCR | Volume | Isat-30% | Irat40 | |

|---|---|---|---|---|

| XRK0730B-100M | 65 | 138.6 | 4.4 | 3.3 |

| XRK0730B Adjustement-100M | 36.1 | 291.6 | 5.1 | 5.3 |

| XRK0754D-100M | 37.4 | 291.6 | 11.5 | 5.2 |

| XRJ0754-100M | 22 | 291.6 | 10 | 6.8 |

XRK-D exhibits more than double the DC superposition capability compared to the B series, while the XRJ series shows slightly lower DC superposition than D.

However, its DCR is significantly lower, making XRJ the best overall performer.

Author

- As some time has passed since the article was written, the information provided may still contain outdated content.

If you have anything, you can send e-mail by clicking here.