Understanding Inductor Core Materials | Ferrite vs. Metal

In today’s inductor market, coil cores are mainly made from two types of materials: ferrite and metal.

Each material has distinct characteristics that affect overall performance.

| Ferrite |  |  |  |

| Metal |  |  |  |

Key Difference: DC Superposition Characteristics

First, a major difference lies in the DC superposition characteristics.

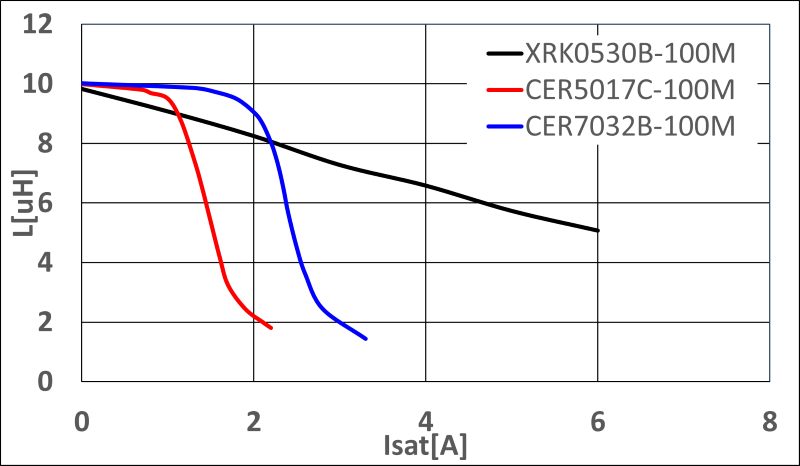

Ferrite and metal cores exhibit significantly different characteristic curves, as shown below.

Metal cores have a higher saturation flux density, allowing them to handle larger currents compared to ferrite.

Example:

At the current where inductance drops by 20%, the ferrite CER5017C shows a significant difference from the metal XRK0530B.

To match the performance of the metal core, a ferrite core two sizes larger, such as CER7032B, is required.

Temperature Stability

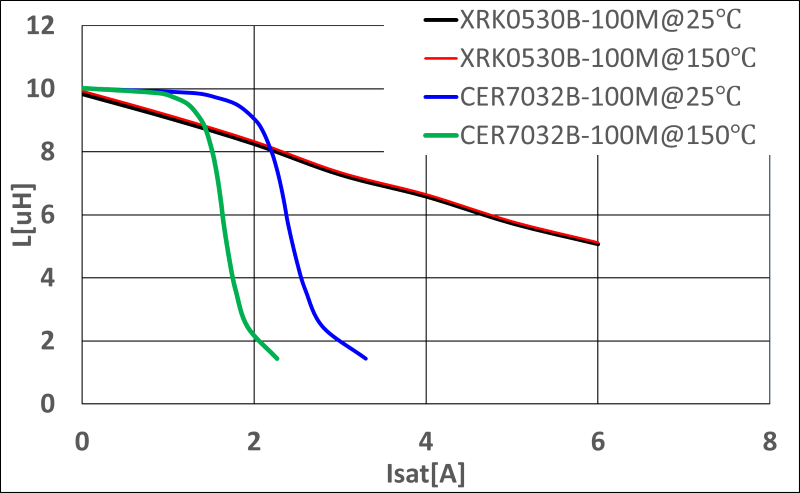

Metal cores are less affected by environmental temperature and maintain their DC superposition characteristics even at the upper limit of the operating temperature range.

Ferrite cores, on the other hand, are temperature-sensitive; their DC superposition characteristics degrade at high temperatures.

Example: The characteristics were equivalent at room temperature, but as the temperature rose, they changed, and CER7032B no longer exhibited the same performance.

Air Gap Structure

The differences in these characteristics arise from the way the air gap mechanism, which suppresses magnetic saturation, is configured.

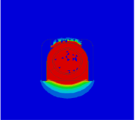

Ferrite cores typically include an air gap in part of the magnetic path.

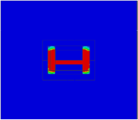

In contrast, the air gap structure of metal cores is fundamentally different. Metal cores are made by mixing micron-scale metal powder with resin. The resin between the metal particles acts as a distributed air gap, causing the magnetic flux to leak more evenly throughout the entire core.

Because of this, even if the effective permeability is the same, the flux leakage behavior differs significantly, causing variations in the DC superposition curves.

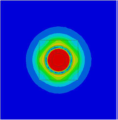

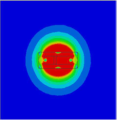

Flux Leakage Comparison

For example, although the products below both appear to have their wire sections covered, the behavior of magnetic flux differs between ferrite and metal cores.

In ferrite cores, magnetic flux primarily leaks from the air gap, while in metal cores, flux leakage occurs more evenly across the entire core.

This difference arises because ferrite cores have high permeability except at the air gap, whereas metal cores have lower, more uniform permeability, resulting in a more evenly distributed flux pattern.

| Ferrite |  |  |  |

| Metal |  |  |  |

Author

- As some time has passed since the article was written, the information provided may still contain outdated content.

If you have anything, you can send e-mail by clicking here.